Stop specifying heavy stone. Stop trusting cheap composite. Here is why Alucore is the only viable option for modern UK architecture.

Most cladding systems are a liability. Solid stone weighs a tonne and requires a structural skeleton that costs more than the facade itself. Solid aluminium is heavy and can warp (“oil-can”) in the summer heat. And cheap composite panels? They are a fire risk and a maintenance nightmare waiting to happen.

If you are a building owner or an architect, you want a facade that stays flat, doesn’t burn, and doesn’t bankrupt the project on structural steel.

That is where Alucore cladding comes in.

This isn’t just another “sandwich panel.” It is an aerospace-grade aluminium honeycomb system that solves the weight problem without sacrificing rigidity.

What on Earth is Alucore? (And Why It’s Not Just “ACP”)

Let’s get the terminology right. Standard “ACP” (Aluminium Composite Panel) often has a plastic core. That is fine for a petrol station sign. It is rubbish for a high-rise building.

Alucore panels are completely different.

- The Skin: Two sheets of high-grade aluminium (usually alloy 5005).

- The Core: An aluminium honeycomb structure. Hexagons.

Why Hexagons?

It is basic physics. The hexagon is the strongest shape in nature for its weight. By sandwiching this honeycomb between two skins, you create a “beam” effect. The panel becomes incredibly stiff but remains 90% air.

Think of it like an aircraft floorboard. It has to take the weight of passengers and trolleys, but it must be light enough for the plane to take off. Alucore cladding systems use this exact technology on your building facade.

The “Peel Strength” Factor

The biggest failure in composite panels is delamination—where the skin peels off the core. Alucore uses a continuous viscoelastic bonding process. It doesn’t just glue the layers; it fuses them. The result is a high “peel strength” that resists wind suction and thermal expansion. Cheap panels do not have this. They pop open after three winters.

UK Compliance: The “CWCT” Standard

If you are working on a major UK project, you need more than just a brochure. You need proof.

Alucore cladding systems supplied by CSS CLADDING LTD are designed to meet CWCT Sequence B testing. This is the industry benchmark for:

- Air Permeability: No drafts.

- Water Penetration: No leaks, even under dynamic wind pressure.

- Impact Resistance: It won’t dent if a window cleaner hits it with a cradle.

In the post-Grenfell era, your PI insurance demands this level of certification. Do not risk using untested “grey market” panels just to save a few pennies.

The Fire Safety Minefield: A1 vs A2

Since the changes to UK building regulations (specifically regarding buildings over 18m), fire safety is the only spec that matters. If it burns, you can’t use it.

There is a lot of confusion between A1 and A2 ratings. Let’s clear it up.

A1 (Non-Combustible)

This is the gold standard. It means the material contributes zero to a fire.

- Solid Aluminium: A1.

- Natural Stone: A1.

- Anodised Alucore: Can be A1 because it has no paint.

A2 (Limited Combustibility)

This is where Alucore cladding panels usually sit.

- Why not A1? It’s the paint. If you apply a PVDF coating thicker than 40 microns for durability, that thin layer of paint technically adds a tiny amount of “fuel.”

- Is it safe? Yes. An A2-s1, d0 rating means it produces very limited smoke (s1) and no flaming droplets (d0). It is fully compliant for high-rise use in most contexts.

Warning: Never use a panel rated B or lower on a high-rise. It is illegal and dangerous. CSS CLADDING LTD only supplies compliant materials. We do not stock the cheap, dangerous stuff.

The “Hidden” Costs of Heavy Cladding

Architects love the look of natural stone. Quantity Surveyors hate the price. But the price of the stone isn’t the problem—it’s the weight.

When you specify concrete cladding boards or heavy stone, you trigger a chain reaction of costs:

- Heavier Steel: The building frame must be beefed up to hold the dead load.

- Deeper Foundations: More concrete in the ground to support the heavier frame.

- Slow Install: You need heavy cranes and more men to lift each slab.

Alucore Cost Calculation

Honeycomb composite panels weigh roughly 5-7kg per square meter.

Solid stone weighs 60-80kg per square meter.

By switching to Alucore (even with a stone-effect finish), you reduce the facade dead load by 90%.

- You use lighter steel sections.

- You pour less concrete.

- Two guys can lift a 3-meter panel by hand.

You don’t just save money on the cladding; you save money on the entire building structure.

Design Freedom: Curves and Finishes

Architects often think “honeycomb” means “stiff and boxy.” Wrong.

You can bend it.

Alucore can be roll-formed or routed to create smooth curves.

- Min Radius: Typically 2x the panel thickness.

- Applications: Curved corners, column covers, and waving roof lines.

Finishes that Last

You have two choices for the look:

- PVDF Coil Coating: Best for colour consistency across large batches. Essential for metallic colours.

- Anodised: The oxide layer is part of the metal. It is harder than paint, but colour matching between batches can be tricky.

Maintenance: The “Set and Forget” Myth

Let’s be honest. No facade is “maintenance-free.” If you don’t clean it, it will look terrible.

However, Alucore is low maintenance compared to stone or timber.

- Frequency: Wash it twice a year (Spring and Autumn).

- The Method: Warm water and a mild, neutral detergent (pH 5-8).

- The Don’ts: Never use alkaline cleaners (like caustic soda) or acidic cleaners. They attack the aluminium.

- Coastal Areas: If you are within 5km of the sea, salt will sit on the panel. You need to wash it every 3 months to prevent pitting.

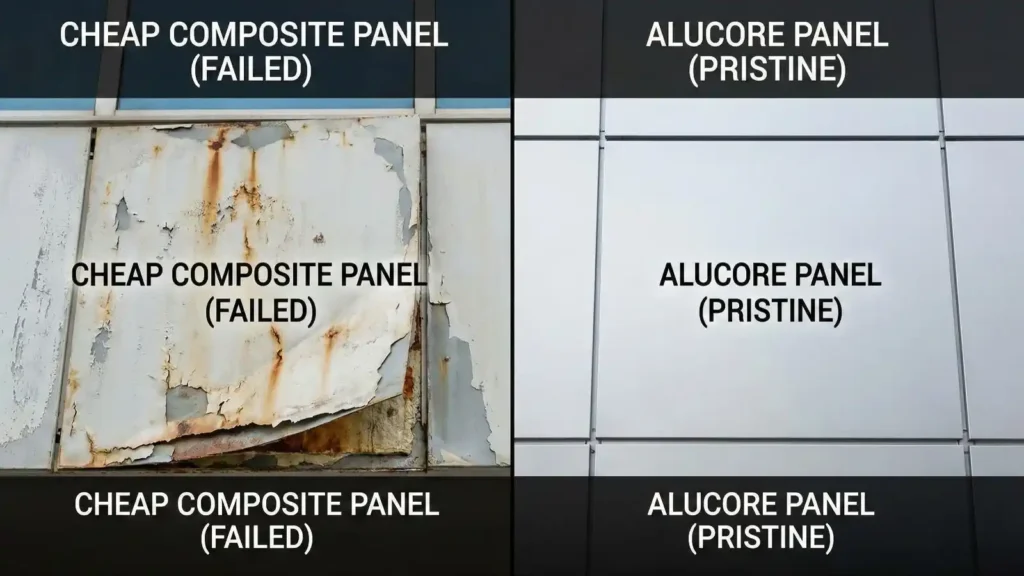

The “Cheap Import” Trap: How to Spot a Fake

There are containers of cheap honeycomb sheets arriving in the UK every day. They look like Alucore, but they are not Alucore.

Here is what happens when you buy cheap:

- Fluid Intrusion:

Cheap panels have weak seals. Water gets inside the hexagonal cells.

- Winter: The water freezes and expands.

- Result: The cells burst. The panel face bulges out. It looks like the building has boils.

- Adhesive Failure:

Budget manufacturers use cheap glue. After two years of UV exposure and thermal cycling (hot/cold), the glue gives up. The aluminium skin delaminates and flaps in the wind.

- The “Oil-Can” Effect:

If the aluminium skin is too thin (below 0.5mm), it will ripple when it gets hot. The facade looks wavy and cheap. Alucore panels use high-tension skins that stay dead flat, even in direct sunlight.

CSS CLADDING LTD guarantees the bond integrity. We do not sell panels that fail after the defects liability period ends.

Alucore vs. Other Claddings

Let’s stop looking at glossy brochures and look at the physics.

In the showroom, every sample looks perfect. But once you bolt a facade to a building and expose it to a British summer (and winter), things change. The biggest enemy of metal cladding isn’t rust—it is “oil-canning.”

This is when solid aluminium sheets expand in the heat. Because they have nowhere to go, they buckle. The result is a facade that looks like a rippled crisp packet when the sun hits it. It ruins the clean lines of the architecture.

Alucore does not do this.

Because of the honeycomb core, the tension is spread evenly across the panel. It stays optically flat, even on huge spans, and even when the temperature swings from -5°C to 30°C.

See for yourself. The image below isn’t a render. It is a real Alucore facade, shot from below. Notice the lines. Dead straight.

Let’s be direct about how this stacks up against the competition.

| Feature | Alucore Cladding | Solid Aluminium | Natural Stone | Cheap Composite |

| Weight | Extremely Low (~5kg/m²) | Heavy (~14kg/m²) | Massive (~60kg/m²) | Low |

| Flatness | Perfect (Stays flat) | Good (Can warp) | Good | Poor (Ripples) |

| Fire Rating | A2 or A1 | A1 | A1 | DANGEROUS (Often B/C) |

| Span Width | Huge spans possible | Limited | Very Limited | Limited |

| Impact Resistance | High (Shock absorbing) | Moderate (Dents) | Brittle (Cracks) | Low |

| CWCT Tested | Yes (System dependent) | Yes | Yes | Rarely |

Sustainability: The Green Argument

Sustainability is not just a buzzword; it is a requirement.

Alucore is 100% recyclable.

When the building is demolished in 50 years, the panels can be melted down and turned into new aluminium. The scrap value alone pays for the removal. Compare that to composite cladding boards filled with plastic or foam. They often end up in landfill because separating the layers is too expensive. If you are chasing a BREEAM rating Excellent or Outstanding, Alucore scores you points for responsible sourcing and recyclability.

Are There Alucore Alternatives? (And When to Use Them)

We believe Alucore is the smartest choice for most modern facades. But is it the only choice? Of course not.

Depending on your budget and aesthetic, you might be looking at other options. Here is an honest look at where they fit.

1. Solid Aluminium (3mm)

- The Good: It is bomb-proof. It is A1 non-combustible.

- The Bad: It is heavy. It relies on stiffeners welded to the back to stay flat. If you skip the stiffeners, it warps in the sun (oil-canning).

- Verdict: Use it for ground-floor areas where trucks might hit the building. Use Alucore for everything above 3 meters to save weight.

2. High-Pressure Laminate (HPL)

- The Good: Massive range of wood and texture finishes. Cheaper than metal.

- The Bad: Fire ratings are a headache. Many HPL panels are combustible. You need to check the data sheet three times before putting this on a high-rise.

- Verdict: Great for low-rise residential or aesthetic features, but risky for tall public buildings.

3. Zinc or Copper

- The Good: They look incredible. They age naturally (“patina”) and change colour over time.

- The Bad: Eye-wateringly expensive. They are also soft metals; a rogue football or a ladder can dent them easily.

- Verdict: Perfect for museums or heritage projects with unlimited budgets. Overkill for an office block.

4. Natural Stone

- The Good: It conveys permanence and prestige.

- The Bad: The weight. We have already discussed this. The structural costs are massive.

- Verdict: If the client demands real Portland Stone, you have to pay the price. If they just want the look, use a stone-effect Alucore panel and save £50,000 on steelwork.

Frequently Asked Questions (FAQs)

Do not compromise on your facade. If you want a building that stands up to the British weather, meets fire regulations, and doesn’t cost the earth to install, you need Alucore.

Contact CSS CLADDING LTD today. Send us your drawings. We will calculate the weight savings and give you a quote that makes sense.

Leave a Reply